What we do

Insert Molding

Insert Molding

Over Molding

Assembly

Rapid Prototyping

Solve Complex Problems

Redesign for Cost Reduction

How we do it

In House

In House

Product Design

Mold Flow & Warp Analysis

Tooling Design

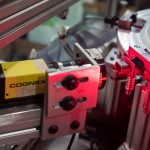

Automation Design & Constructions

Additional Process Capabilities

Automated and Manual Assembly

Automated and Manual Assembly

Terminal Insertion (stitching)

Robotic Soldering

Ultrasonic Welding

Robotic Application of Cure in Place Materials

Metal Stamping

Laser Marking

Wire Assemblies

Supply Chain Management

Fully Integrated ERP System

Fully Integrated ERP System

EDI Capabilities

Finished Goods Warehousing

Worldwide Services

Risk-based Supplier Qualification Auditing & Management

Domestic & International Supply Base

Contingency Planning Through All Layers of the Supply Chain